Where Flexibility Meets Durability: Printing on Continuous Webs with UV-Cured Inkjet Technology

When it comes to flexible packaging, manufacturers face a tough challenge: how do you print variable data, crisp graphics, and high-resolution barcodes on films and continuous webs—while still ensuring durability for shipping, handling, and retail environments?

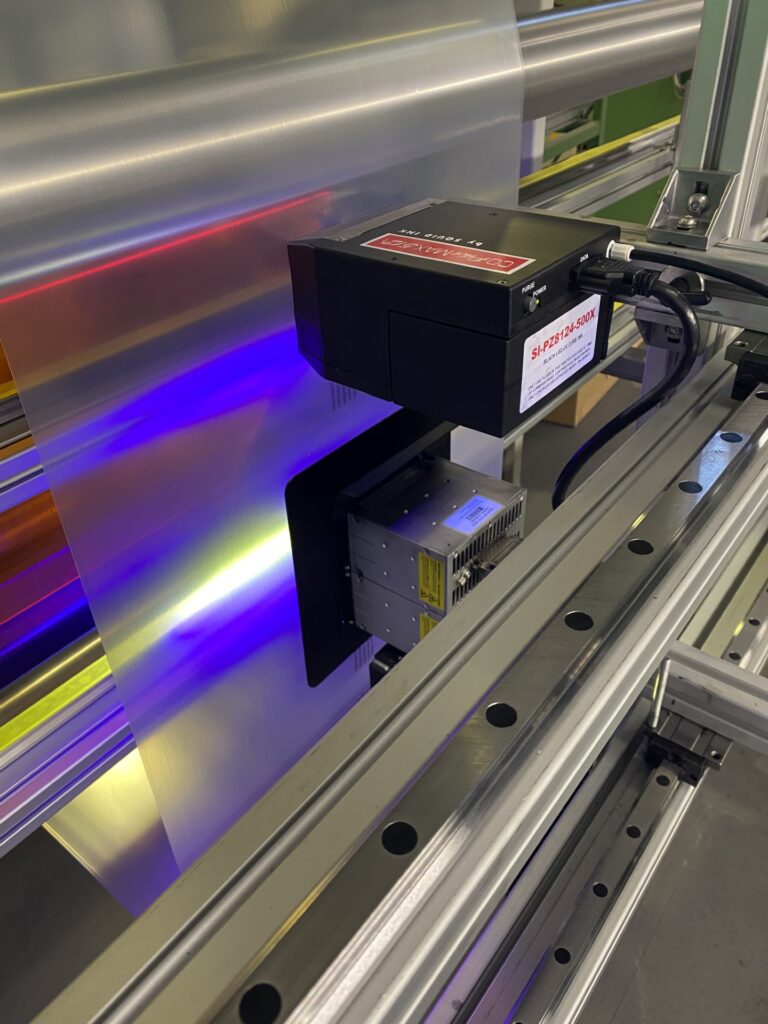

At Squid Ink, we’ve engineered the perfect solution: our CoPilot® Family of Printing Systems paired with UV LED Curing Equipment. This powerful combination delivers precision, permanence, and production efficiency for today’s most demanding packaging needs.

Precision Printing with CoPilot® Systems

At the heart of the solution is Squid Ink’s CoPilot Printing Systems, powered by advanced Piezo inkjet technology. These printers make it easy to handle a wide range of applications, from:

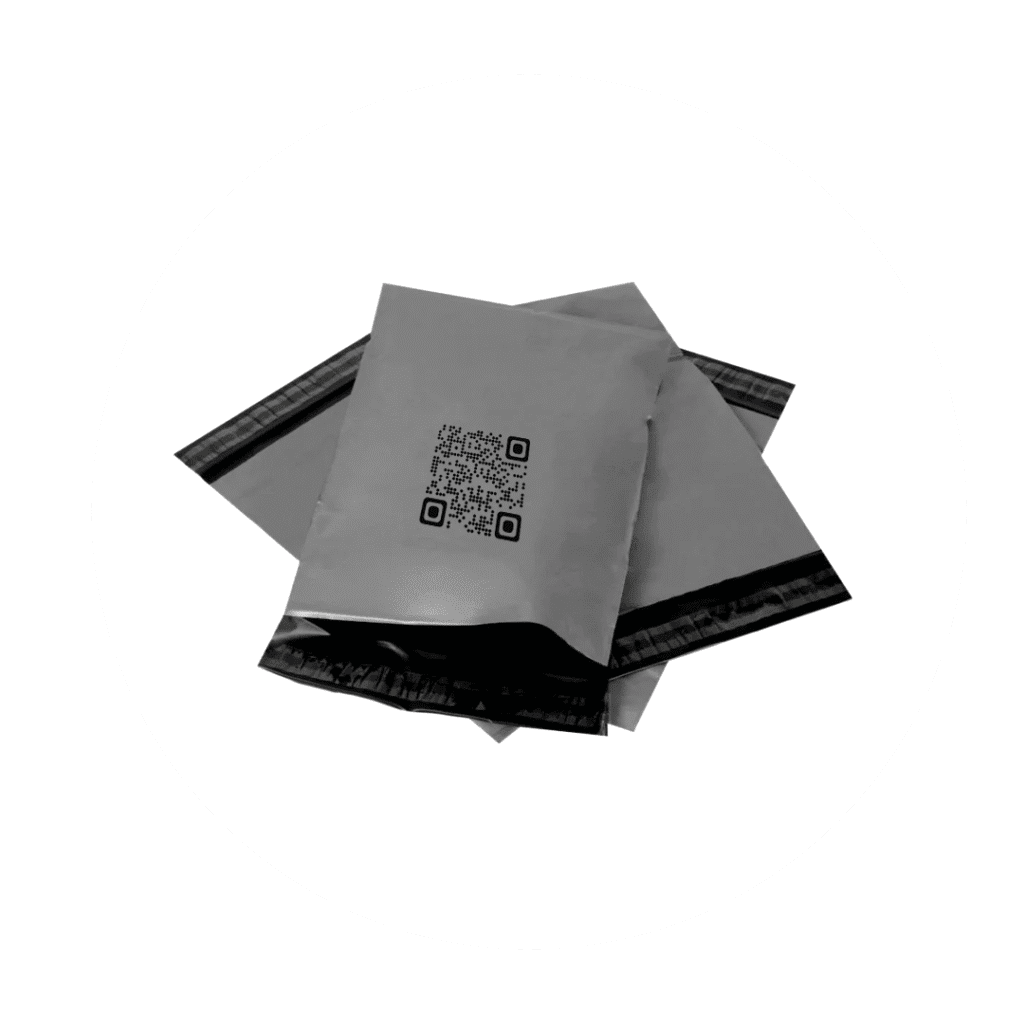

- High-resolution QR codes and barcodes for compliance and traceability

- Logos, branding, and crisp graphics for shelf appeal

- Lot-specific variable data for better inventory management and recalls

Every mark is sharp, consistent, and ready to meet the challenges of modern supply chains.

Permanent Prints with UV LED Curing

Pairing our printers with Squid Ink’s UV LED Curing Equipment takes performance a step further. With instant curing, your prints are:

- Durable – resistant to abrasion, moisture, and handling

- Fast – dry the moment they’re printed, keeping production lines moving

- Versatile – capable of printing on a wide range of flexible films and substrates

This means your packaging is not only compliant but also built to last through distribution and customer use.

Trusted Across Industries

Our solutions are already at work in plants around the world. A few examples include:

- Postal Bags – QR codes printed for tracking and logistics

- Garden Compost & Pet Food Bags – durable branding on heavy-duty films

- Food Waste Bags – clear labeling for sustainable disposal

- Polythene Sheeting – diverse graphics and data on industrial materials

No matter the application, Squid Ink helps manufacturers balance flexibility with durability—all while keeping production efficient.

Preparing for Sunrise 2027

With GS1 Sunrise 2027 on the horizon, the ability to print compliant 2D barcodes (like QR codes) directly onto flexible films is more important than ever. Retailers and regulators are demanding smarter, data-rich labels, and Squid Ink is here to help you stay ahead.

Our inkjet + UV LED curing systems ensure your operation can produce compliant, scannable QR codes in a clean, fast, and reliable process—future-proofing your packaging for the connected supply chain.

The Perfect Solution for Your Operation

From variable data to vibrant branding, from food safety compliance to consumer engagement—Squid Ink delivers printing systems built for today and ready for tomorrow.

Where flexibility meets durability, Squid Ink is your partner in packaging innovation.