CoPilot Flex Hi-Resolution Printer

- CoPilot Flex uses proven Xaar piezo technology resulting in razor-sharp print

- Solvent-based for a variety of applications such as pulp, PET, foam egg cartons, glossy or uncoated cases, and more

- Print up to .7″ of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi

The CoPilot Flex Hi-Resolution Printing System

The CoPilot® Flex is designed to print superior quality hi-resolution characters, razor-sharp text, real-time information, scannable bar codes, and great looking logos on pulp, foam, or PET egg cartons. With up to .7” of print height and the ability to print multiple lines of information in a single pass, the CoPilot Flex is designed to streamline your printing process.

Minimal Footprint, Maximum Results

CoPilot Flex is engineered for simple integration on your existing egg packing line or wherever space constraints are an issue. The system’s unique and compact design allows for narrow mounting in nearly every zone of your egg packing process, eliminating the need for after-market engineering or time-consuming modifications to your existing conveyor. CoPilot Flex’s small printhead adjusts to match the slope of the carton to ensure a quality hi-resolution print. The system is capable of inverting your printed message, if needed, meaning you can print your cartons in the open or closed carton zone. At print speeds of up to 135 ft/minute, the CoPilot Flex is sure to keep your production moving.

Keep Your Production Running

CoPilot Flex’s 200ml ink cartridge contains nearly 5 times the amount of ink compared to many competitor’s cartridges. The increased ink volume and convenient cartridge design result in less frequent changeover and reduced production downtime. Even better, Squid Ink’s SI-PZ4200 solvent-based ink jet ink has been designed and tested for excellent adhesion properties on pulp, foam, and clear PET egg cartons while providing dark print that is easy to read.

CoPilot Flex’s compact printhead is designed to match the slope of the egg carton, resulting in highquality print.

The unique design of the CoPilot Flex allows for parallel conveyor mounting to maximize available aisle space.

200ml ink cartridges offer simple and clean ink changes.

CoPilot Flex’s 4.3” full color touchscreen provides access to the systems internal messages and print functions.

Manage messages wirelessly using the optional 10.1” full color touchscreen with Orion Software

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards

BENEFITS OF THE COPILOT FLEX

- CoPilot Flex uses proven Xaar piezo technology resulting in razor-sharp print

- Solvent-based for a variety of applications such as pulp, PET, foam egg cartons, glossy or uncoated cases, and more

- Print up to .7″ of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi

- CoPilot Flex’s 4.3″ full color touchscreen provides access to the system’s internal messages and print functions

- Compatible with Squid Ink’s easy-to-use Orion™ message creation PC software

SYSTEM SPECIFICATIONS

- Print Technology – Piezo impulse printhead technology

- Maximum Print Height – .7” (1.8 cm) per printhead

- Vertical Print Resolution – 185 dpi capable of printing razor-sharp graphics, small character text, and scannable bar codes

- Horizontal Print Resolution – 205 dpi

- Print Speed – Up to 135 feet/min. (41 m/min.) @ 205 dpi standard, optional high speed printhead up to 200 feet/min (60 m/min)

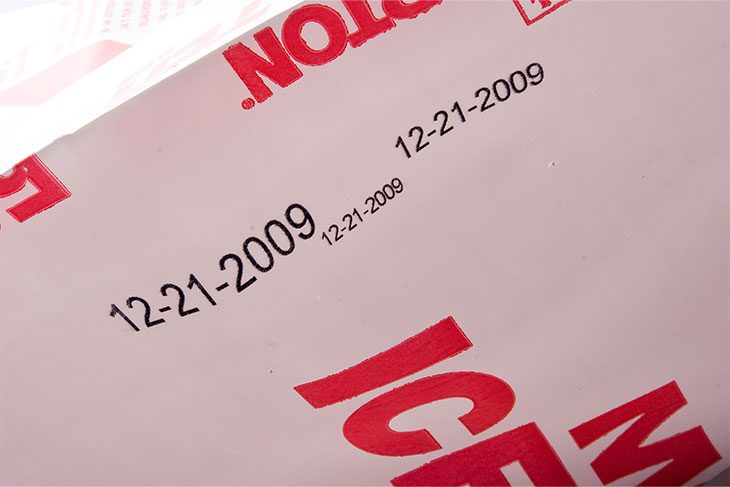

- Time & Date – Internal real time clock with battery back-up

- Product Sensor – External diffuse beam photocell standard

- Communication Interface – One USB host and one Ethernet input

- Touchscreen – 4.3” (10.9 cm) full color touchscreen display

- Ink Cartridge Volume – 200ml cartridge

- Low Ink Indicator – Status alert on touchscreen, LED light beacon optional

- Substrate Capabilities – Non-Porous surfaces

- Electrical Requirements – 100 – 240 VAC, 50/60 Hz

- Operating Environment – 34°F – 104°F (1° – 40°C)

- Conveyor Mounting Bracket – Provides stable mount to conveyor or other material handling equipment

- Agency Certifications – CE, TUV, FCC, UL, CSA

SOFTWARE SPECIFICATIONS

- Time & Date – Full time and date functionality including expiration date and Julian Dates

- Item Numbering – Sixteen counters, one of which can be a daily counter and production counter

- Shift Codes – Four programmable shift codes with automatic rollover

- Bar Codes – All standard bar codes including 2D

- Fonts – Arial, Arial Bold, Arial International, Arial Monospaced, Courier, Tahoma Bold and Lucida resident fonts for use in variable data elements. Static elements in any Windows® font

- Logos – Most image files supported with Orion software

- Printing Features – Reverse, invert, rotate, repeat. Print on/off button

- Message Length – Up to 180”

- Number of Messages – 4GB storage space will store approximately 1000+ messages

- Ink Usage – Shown in Orion software

- User Data Prompts – Prompts for user input at start of print job by manual input on touchscreen

- Bluetooth Connectivity – For connectivity with Bluetooth keyboards

- Wireless Connectivity – For wireless connection between PC or tablet and printer controller

- Database Capability – Ethernet communication protocol for external communication

- Languages – English, Spanish, German, Chinese, Japanese, Korean, Russian

OPTIONAL ACCESSORIES

- Encoder – For operation with variable speed conveyors

- Bar Code Laser Scanner – Allows scan and print message retrieval

- External Light Beacon – Indicates low ink levels

- Wireless USB Device and Router – For wireless connectivity

- Windows Tablet Pre-loaded with Orion software; includes mounting bracket with swivel arm, USB to ethernet cable and stylus

- Starter Kit – Includes ink, cleaner and flush solution, printhead wipes, hand cleaner and latex gloves

Looking for Replacement Ink Jet Inks and Fluids?