BAKE. MARK. DELIVER.

Reliable Traceability With Squid Ink

TRACEABILITY MADE SIMPLE FOR BAKERY PRODUCTS

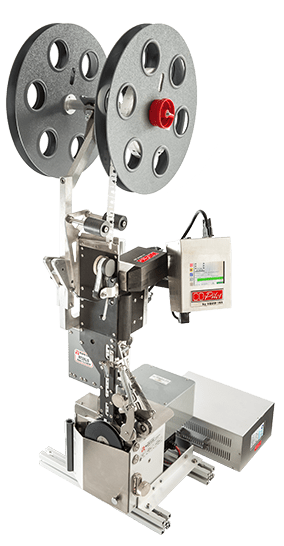

CLOSURE MARKING & CODING MADE EASY Why Choose Squid Ink’s UV LED Printing System?

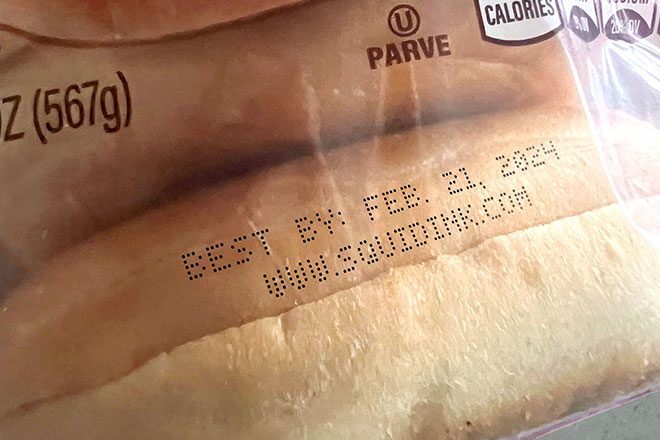

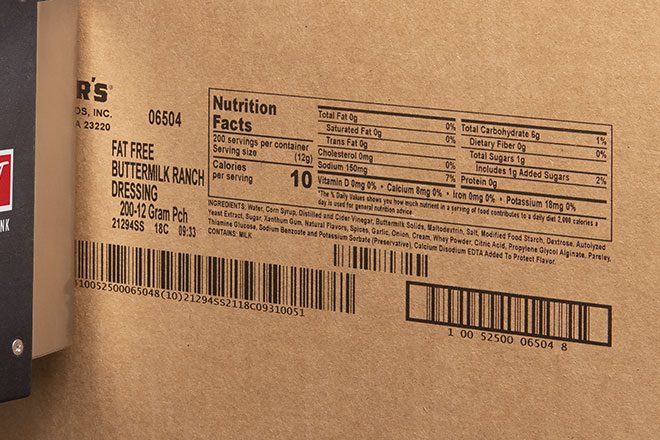

Squid Ink’s UV LED curing technology delivers a low-maintenance, high-performance solution for printing sell-by dates, suggested prices, and 2D barcodes on bakery bag closures and other packaging materials.

KEY BENEFITS OF UV LED INK TECHNOLOGY

- No Drying Until You’re Ready – Ink stays fluid until cured by UV LED light, preventing dry out and reducing maintenance.

- Instant Curing – Prints dry immediately—no waiting, no smudging!

- Permanent & Durable – Smudge-proof, waterproof, and resistant to sunlight, moisture, and temperature changes.

- Eco-Friendly – Virtually no VOCs; a safe, sustainable solution for food applications.

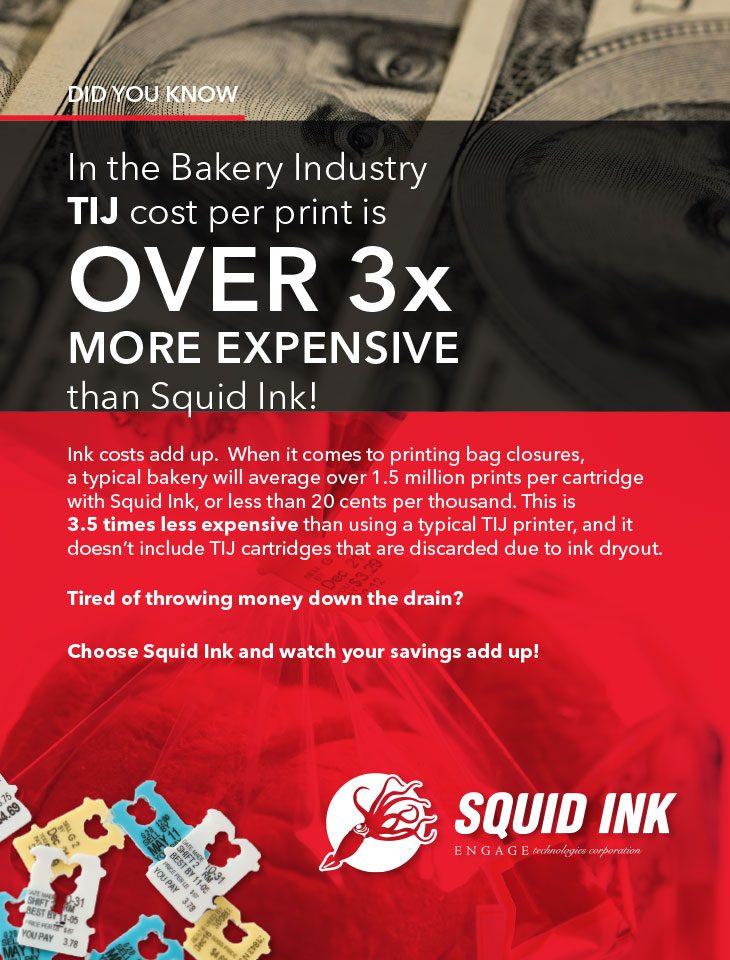

- Cost-Effective – Typical ink yield of 1.5 million prints per cartridge—just 20¢ per 1,000 closures!

UPGRADING FROM OTHER PRINT TECHNOLOGIES?

Here’s Why Bakeries Are Switching from TTO, CIJ, and TIJ

PROVEN PERFORMANCE YOU CAN TRUST

Squid Ink provides reliable, high-quality printing solutions for:

- Bag closures and closure tape

- Bakery bags

- Corrugate shipping cases and trays

- Direct-to-package marking applications

Trusted by some of the nation’s largest bakeries, Squid Ink systems deliver durability, consistency, and value—keeping your products traceable and compliant from oven to shelf.