SquidCheck Print Validation System

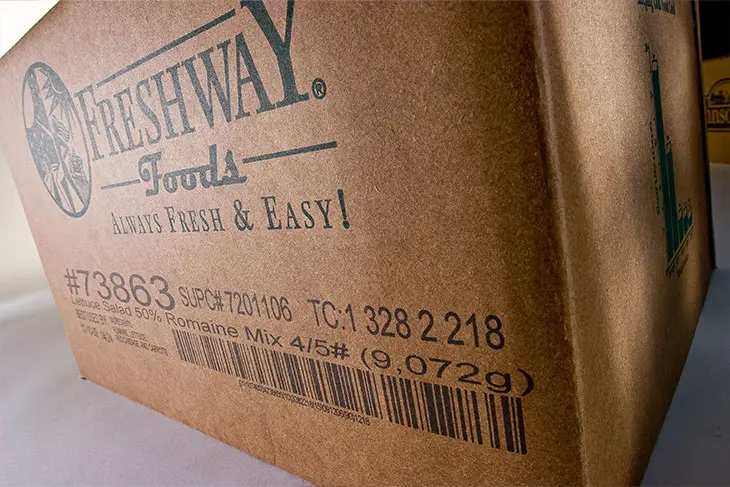

SquidCheck™ offers print and verification of the bar codes printed on your cases, trays, pipe, or other products. SquidCheck utilizes bar code readers from Cognex®, the world’s most trusted machine vision and industrial bar code reading company. The reader is integrated with a Squid Ink printer and SquidCheck interface to ensure that codes are present, scannable, and accurate.

Identify & Eliminate Failures From Your Production Line

SquidCheck allows users to automatically take control of your packaging line. Once a code is printed, the reader reads the code while SquidCheck communicates with the printer to confirm that this is the correct code to be printed. Code failures are identified and rejected as desired while SquidCheck safeguards that only correct and properly coded products advance to the next stage of your production line.

Capture Performance Data From Every Code

Performance data is captured, stored, and can be transferred to your business systems for evaluation or enhanced visibility. Users can receive images and feedback of each and every code, or just the errors as desired.

Analyze Print Data & Make Improvements

The SquidCheck system gathers valuable data on reader and printer performance, and automatically catalogues each code. By analyzing data trends, users can identify issues due to poor printer setup or maintenance and help improve their overall coding performance.

SquidCheck is integrated with a Cognex® reader and Squid Ink printer to ensure that codes are present, scannable, and accurate.

Cognex readers offer straight or right-angled configurations to fit into the tightest spaces.

SquidCheck software gathers valuable data on reader and printer performance and allows user to improve their overall coding operation.

SquidCheck offers print and validation of 1D or 2D bar codes printed on all of your products.

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards