905 Series for Kwik Lok Systems Bakery

The 905 Series CoPilot UV LED Curing System integrated with Kwik Lok’s 872 or 893 Automatic Bag Closing Machine provides an ideal solution for bakeries printing sell by dates, suggested list prices, and 2D bar codes on bakery bag closures.

Make a Mark That Lasts

Squid Ink’s UV LED curing technology features a low maintenance ink cured only by UV LED light. The ink won’t dry until it comes in contact with the UV light, meaning a lower maintenance solution than all other ink jet technologies. This instant LED curing ink leaves a permanent mark that is impervious to environmental factors such as sunlight, water, moisture, temperature, and contains virtually no VOCs, making it ideal for food applications. Additionally, the 905 Series CoPilot system utilizes easy-to-use software modified specifically for the baking industry for easy message programming and recall.

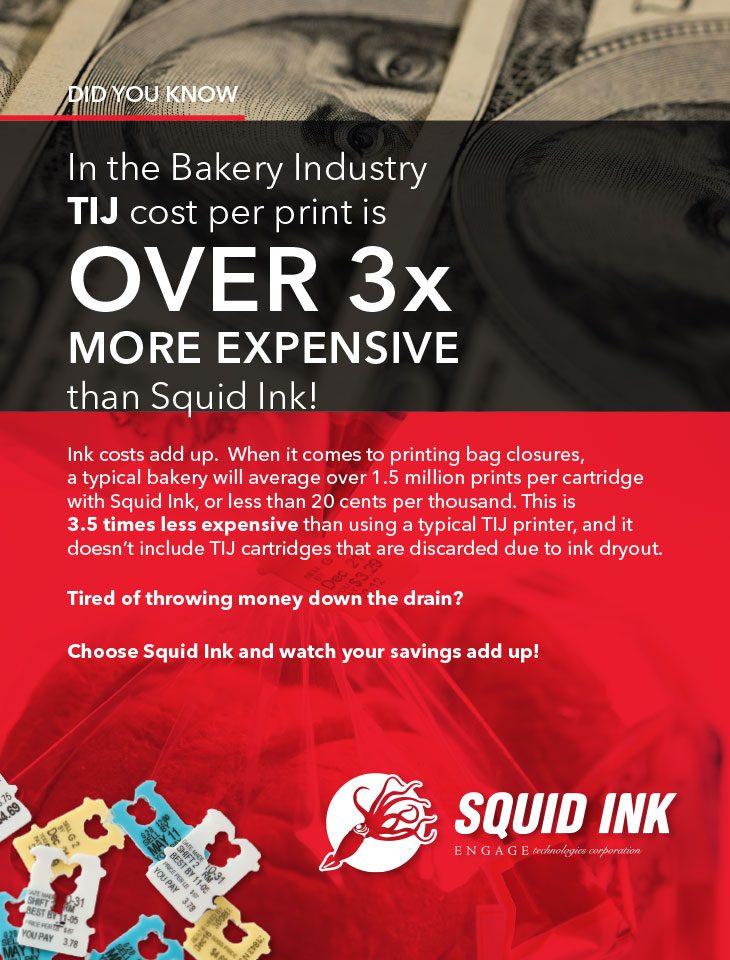

Out With the Old, In With the New

UV LED technology offers several advantages over existing TTO (thermal transfer overprint) systems currently used in bakery applications. Squid Ink’s 905 Series CoPilot system does not require compressed air, making it an easy install anywhere in the plant. In addition, the 905 Series offers 20-25 times fewer ink/ribbon changes, and up to 5 times lower cost per print. Typical cost per print is 20 cents per 1,000 loks. Add in a longer printhead life span and no work stoppages for ribbon breaks, and users will enjoy increased savings on their initial and ongoing operating costs.

Designed for Durability

Squid Ink’s 905 Series CoPilot UV LED Curing System is designed to meet the demands of your application. You can be confident that the 905 Series CoPilot’s rugged design will withstand your baking environment while providing superior quality print and UV curing. For ease of integration, the 905 mounts directly to Kwik Lok’s 872 or 893 Closure Machines and requires no need for preheating or compressed air. The 905 UV LED system can be prgrammed to run in manual, semi-automatic, or automatic mode to match the operation of your manufacturing line. For quick start-ups, 905’s fast response functionality means that the system can be powered on and ready to go at an instant, eliminating downtime and increasing your ROI.

The system is ideal for printing sell by dates, suggested list prices and 2D bar codes on bakery bag closures.

A 4.3” full color touchscreen provides access to the systems internal messages and print functions.

Squid Ink’s low-maintenance UV LED instant curing system provides a permanent mark with no VOCs.

905 Series offers up to 5 times lower cost per print than competitive systems – typical cost per print is 20 cents per 1,000 loks.

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards