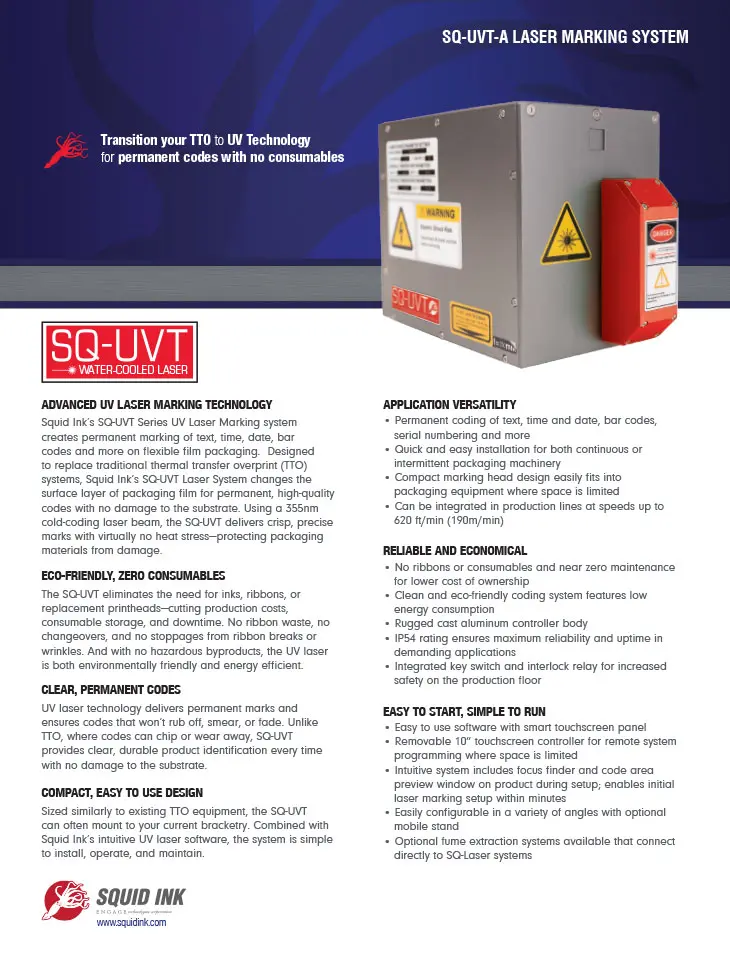

SQ-UVT Laser Marking System

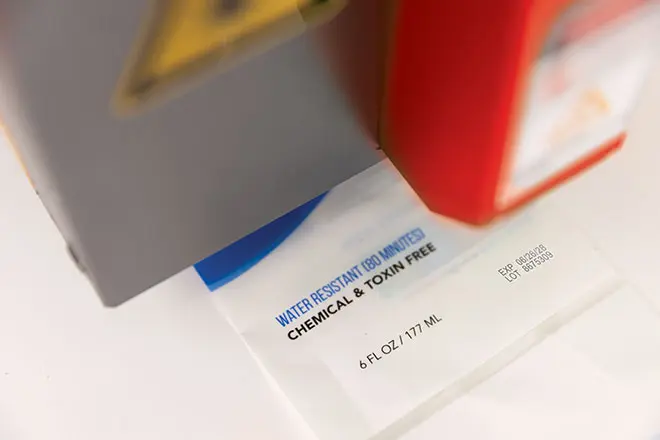

- Permanent coding of text, time and date, bar codes, serial numbering and more

- Quick and easy installation for both continuous or intermittent packaging machinery

- Compact marking head design easily fits into packaging equipment where space is limited

- Can be integrated in production lines at speeds up to 620 ft/min (190m/min)

Advanced UV Laser Marking Technology

Squid Ink’s SQ-UVT Series UV Laser Marking system creates permanent marking of text, time, date, bar codes and more on flexible film packaging. Designed to replace traditional thermal transfer overprint (TTO) systems, Squid Ink’s SQ-UVT Laser System changes the surface layer of packaging film for permanent, high-quality codes with no damage to the substrate. Using a 355nm cold-coding laser beam, the SQ-UVT delivers crisp, precise marks with virtually no heat stress—protecting packaging materials from damage.

Eco-friendly, Zero Consumables

The SQ-UVT eliminates the need for inks, ribbons, or replacement printheads—cutting production costs, consumable storage, and downtime. No ribbon waste, no changeovers, and no stoppages from ribbon breaks or wrinkles. And with no hazardous byproducts, the UV laser is both environmentally friendly and energy efficient.

Clear, Permanent Codes

UV laser technology delivers permanent marks and ensures codes that won’t rub off, smear, or fade. Unlike TTO, where codes can chip or wear away, SQ-UVT provides clear, durable product identification every time with no damage to the substrate.

Compact, Easy To Use Design

Sized similarly to existing TTO equipment, the SQ-UVT can often mount to your current bracketry. Combined with Squid Ink’s intuitive UV laser software, the system is simple to install, operate, and maintain.

Sized similarly to existing TTO equipment, SQ-UVT can often mount to your current bracketry.

Transition your TTO to UV Technology for permanent codes with no consumables.

Easy to use 10” touchscreen controller mounts to cabinet for system configuration and message programming.

An integrated key switch and interlock relay is included for safety on the production floor.

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards