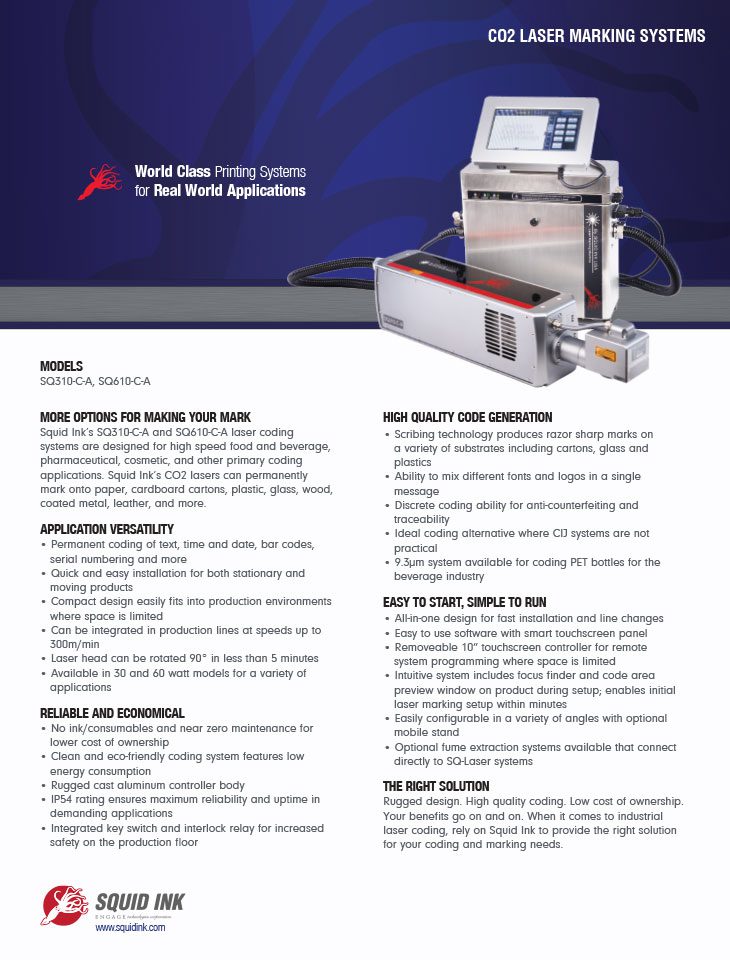

CO2 Laser Marking Systems SQ310-C-A & SQ610-C-A

Squid Ink’s SQ310-C-A and SQ-610-C-A laser coding systems are designed for high speed food and beverage, pharmaceutical, cosmetic, and other primary coding applications. Squid Ink’s CO2 lasers can permanently mark onto paper, cardboard cartons, plastic, glass, wood, coated metal, leather, and more.

Application Versatility

- Permanent coding of text, time and date, bar codes, serial numbering and more

- Quick and easy installation for both stationary and moving products

- Compact design easily fits into production environments where space is limited

- Can be integrated in production lines at speeds up to 300m/min

- Laser head can be rotated 90° in less than 5 minutes

Reliable & Economical

- No ink/consumables and near zero maintenance for lower cost of ownership

- Clean and eco-friendly coding system features low energy consumption

- Rugged cast aluminum controller body

- IP54 rating ensures maximum reliability and uptime in demanding applications

- Integrated key switch and interlock relay for increased safety on the production floor

High Quality Code Generation

- Scribing technology produces razor sharp marks on a variety of substrates including cartons, glass and plastics

- Ability to mix different fonts and logos in a single message

- Discrete coding ability for anti-counterfeiting and traceability

- Ideal coding alternative where CIJ systems are not practical

- 9.3μm system available for coding PET bottles for the beverage industry

Easy to Start, Simple to Run

- All-in-one design for fast installation and line changes

- Easy to use software with smart touchscreen panel

- Removable 10” tethered touchscreen controller for remote mounting where space is limited

- Intuitive system includes focus finder and code area preview window on product during setup; enables initial laser marking setup within minutes

- Easily configurable in a variety of angles with optional mobile stand

- Optional fume extraction systems available that connect directly to SQ-Laser systems

An optional heavy duty stand is available to simplify setup and install the system in a variety of configurations.

The laser head can be rotated 90 degrees in less than 5 minutes.

Easy to use 10” touchscreen controller mounts to cabinet for system configuration and message programming.

An integrated key switch and interlock relay is included for safety on the production floor.

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards