CoPilot 256 Hi-Resolution Printer

- CoPilot 256 uses proven Xaar piezo technology resulting in razor-sharp print

- Available in either oil-based for porous applications or solvent-based for non-porous applications

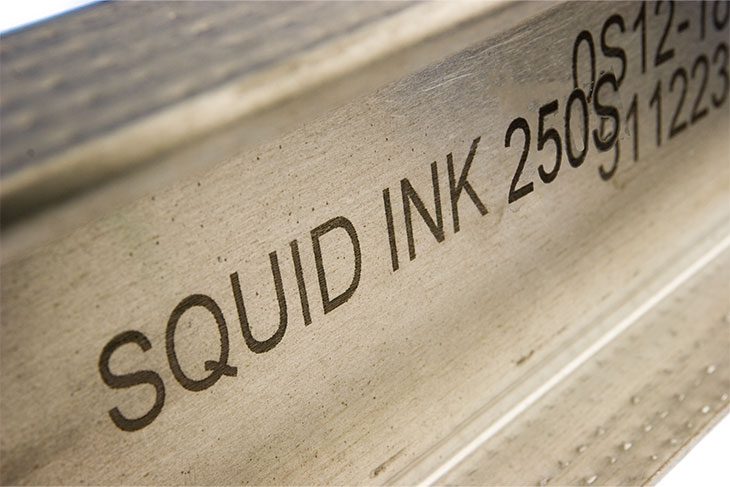

- Print up to 1.4″ of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi from a single print head

- CoPilot 256’s 4.3″ full color touchscreen provides access to the system’s internal messages and print functions

Hi-Resolution Printing System

The CoPilot 256 ink jet printer is designed to print superior quality hi-resolution characters on either porous or non-porous surfaces. With up to 2.8” of total print height and the ability to print on both sides of the substrate in a single pass, the CoPilot 256 is designed to work as an integral part of your day-to-day packaging operation.

Increased Application Versatility

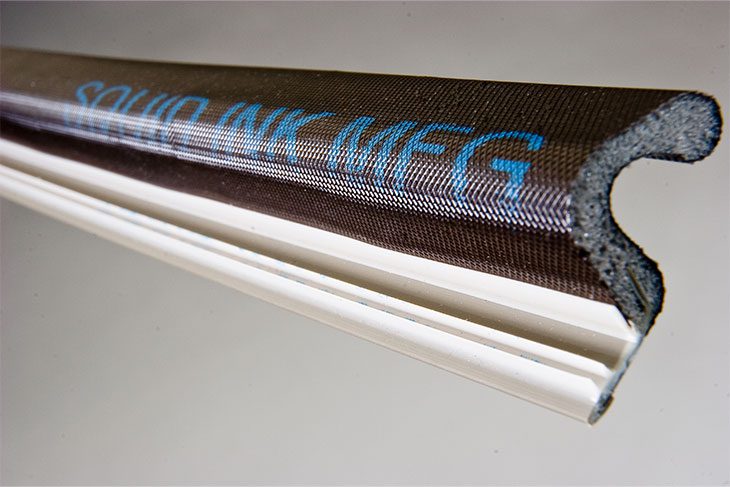

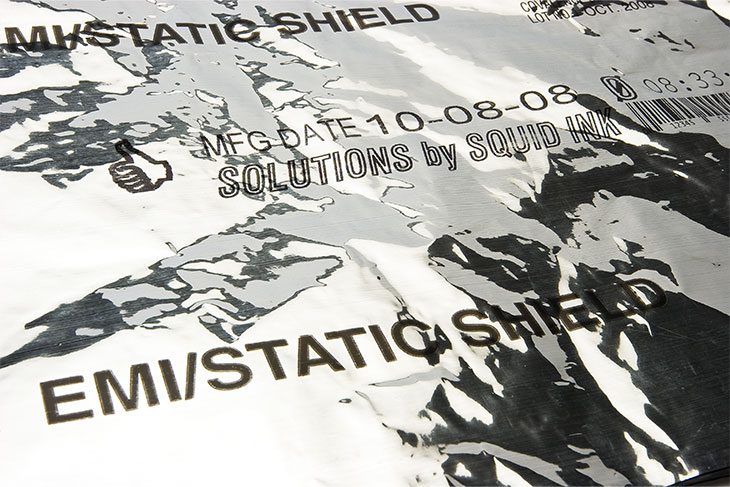

The system is capable of running oil-based or solvent-based inks to print up to 2.8” (1.4” from a single head) of hi-resolution characters, razor-sharp text, scannable bar codes, and great looking logos at 185 dpi. For non-porous applications, users have the option of using Squid Ink’s solvent-based inks for printing on a variety of products like coated cartons, plastics, glass, shrink wrap, metals and more. Squid Ink’s PZ-1000 ink for porous substrates offers low-maintenance performance, eliminating the need for auto-priming functions and offering better ink utilization than competitive systems.

User-Friendly System

CoPilot 256’s 4.3” full color touchscreen provides access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via Ethernet or USB device. For larger applications, a virtually unlimited number of CoPilot 256 printing systems can be connected via Ethernet and controlled through one central Orion™ print station.

The CoPilot 256 utilizes oil-based or solvent-based inks for printing on a wide range of porous or non-porous substrates.

The system has the flexibility to be configured to print horizontally, at an angle, or in down shooter position.

A 4.3” full color touchscreen provides access to the systems internal messages and print functions.

The bag ink agitator system is an ideal solution for users printing with pigmented inks.

Manage messages wirelessly using the optional 10.1” full color touchscreen with Orion Software

Squid Ink is a GS1 US Solution Partner, dedicated to helping businesses implement GS1 standards

Looking for Replacement Ink Jet Inks and Fluids?