CoPilot Max with Solvent Capability SQUID INK INTRODUCES NEW COPILOT® MAX 360DPI PRINTING SYSTEM NOW WITH SOLVENT CAPABILITY

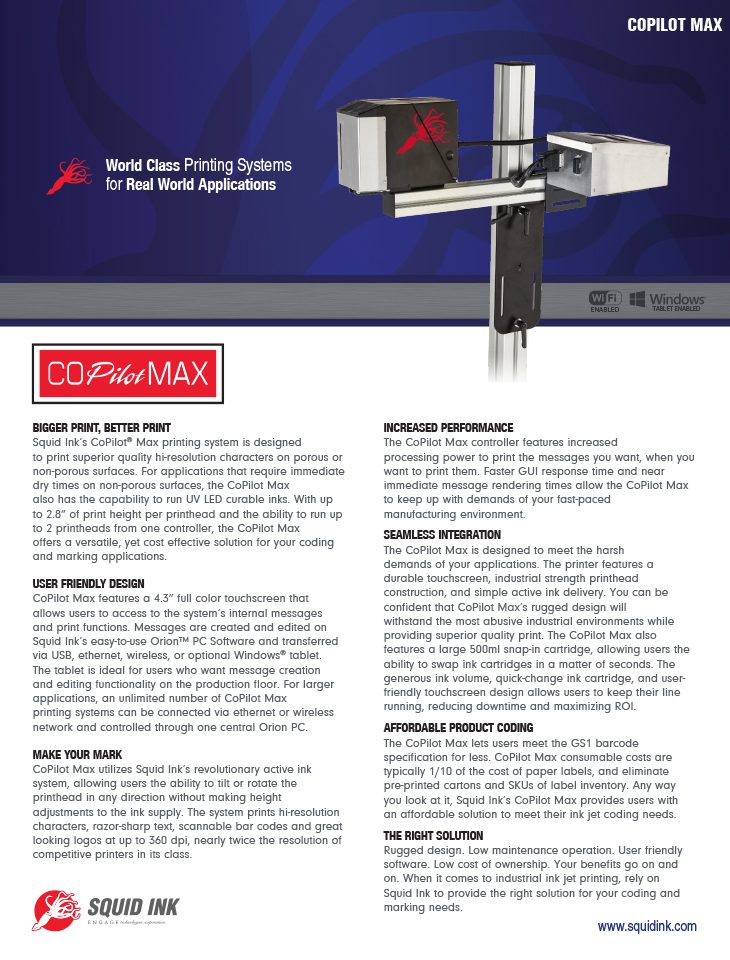

January 6, 2020, Brooklyn Park, MN – Squid Ink Manufacturing, Inc., a leading manufacturer of coding and marking systems for product identification and traceability, introduces the CoPilot Max Turbo printing system now with solvent capability to print on non-porous surfaces. With up to 2.8” of print height per printhead and the ability to run up to 2 printheads from one controller, the CoPilot Max Turbo offers a versatile, yet cost effective solution for a variety of product coding and marking applications.

Intially released in October 2019 with oil-based ink capability, the CoPilot Max Turbo now has the capability to run solvent-based inks, allowing users the ability to print on coated corrugate, polystyrene, films, and a number of other non-porous surfaces. Solvent-based capability is ideal for users looking to replace expensive labels and print directly on glossy cartons, cases, trays, or other non-porous substrates.

The CoPilot Max Turbo utilizes Squid Ink’s revolutionary active ink system, allowing users the ability to raise, lower, tilt, or rotate the printhead without making height adjustments to the ink supply. The system prints hi-resolution characters, razor-sharp text, scannable bar codes and great looking logos at up to 360 dpi, nearly twice the resolution of competitive printers in it’s class.

The printer features a durable touchscreen, industrial strength printhead construction, and simple active ink delivery. The CoPilot Max Turbo also features a large 500ml no-mess snap-in cartridge, allowing users the ability to swap ink cartridges in a matter of seconds. The generous ink volume, quick-change ink cartridge, and user-friendly touchscreen design allow users to keep their line running, reducing downtime and maximizing ROI.

The CoPilot Max Turbo features a full color touchscreen that allows users access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to-use Orion™ PC Software and transferred via USB, ethernet, wireless, or optional

Windows® tablet. The tablet is ideal for users who want message creation and editing functionality on the production floor. For larger applications, an unlimited number of CoPilot Max Turbo printing systems can be connected via ethernet or wireless network and controlled through one central Orion PC.

The CoPilot Max Turbo with solvent printing capability is available now through Squid Ink’s worldwide network of authorized distributors. Sales inquiries should be directed to Joshua Nelson, Squid Ink Manufacturing, Inc., 7041 Boone Ave. N., Brooklyn Park, MN 55428.

1-800-877-5658. jnelson@squidink.com

Squid Ink, Eastey, American Film & Machinery (AFM) and Cogent Technologies are all divisions of Engage Technologies Corporation. Squid Ink (squidink.com) is a manufacturer of coding and marking systems for product identification and traceability, providing superior quality inks and low maintenance printing equipment. Eastey (eastey.com) is a leading manufacturer of heavy-duty shrink packaging equipment and automated case sealing systems for packaging applications. American Film & Machinery (afmsleeves.com) supplies shrink labelers and tunnels, shrink sleeves, and tamper evident bands. Cogent Technologies (cogent-tech.com) manufactures infrared drying systems used to dry ink in the industrial and graphics industries.

Engage Technologies Corporation is headquartered in Brooklyn Park, MN with facilities in Rogers, MN, Spring Lake Park, MN, The Hague, Netherlands, and Shanghai, China. The Company continues to expand sales and services, with authorized distributors strategically located throughout the U.S. and the rest of the world.

###

For press information, please contact:

Joshua Nelson

Squid Ink Manufacturing, Inc.

(763) 795-8856, ext. 1735

jnelson@squidink.com

Photos available via e-mail – please e-mail jnelson@squidink.com for details.