How to Choose the Right Print Speed, Quality, and Volume for Your Production Line?

Choosing the right industrial printer isn’t just about buying the fastest or highest-resolution system on the market. The real goal is to match print speed, print quality, and production volume, to your current operation—while ensuring you’re ready for what’s next.

Here’s how to evaluate each factor and select a solution that delivers long-term value.

1. Print Speed: Keeping Up Without Overpaying

Print speed is typically measured in prints per minute (PPM) or inches per minute (IPM). The right speed depends on your line rate, product spacing, and the type of marking required.

Ask yourself:

- How fast does my conveyor run today?

- Will I increase line speeds in the next 1–3 years?

- Do I need consistent print quality at higher speeds?

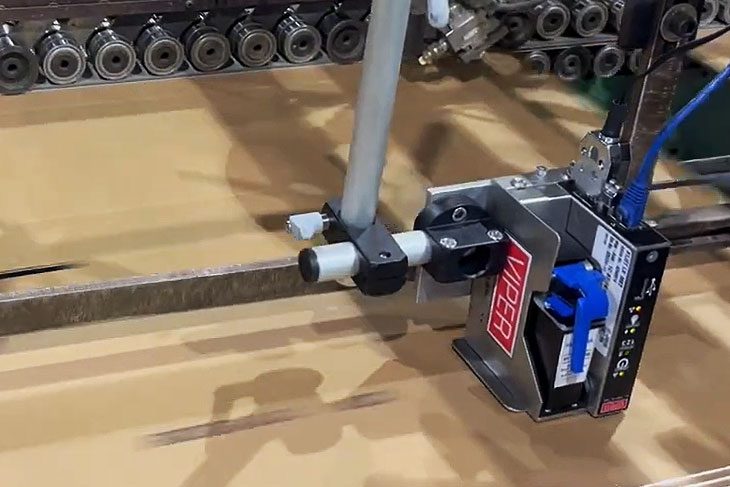

Many production lines don’t need ultra-high speeds—but they do need reliability. Squid Ink systems are designed to maintain clean, legible marks across a wide range of line speeds, helping manufacturers avoid paying for speed capacity they’ll never use while still supporting future growth.

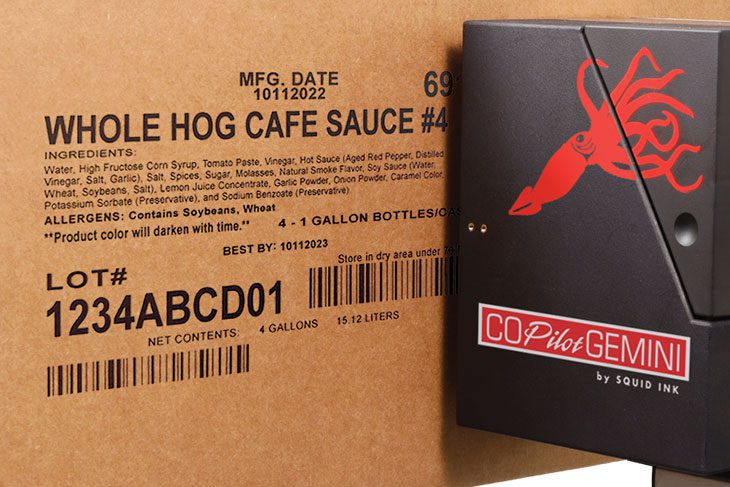

2. Print Quality: Choosing the Right Resolution (DPI)

Print quality is measured in dots per inch (DPI), and higher isn’t always better—it just needs to be right for your application.

General guidelines:

- Low to mid DPI: Large characters, case codes, pallet markings

- High DPI: Barcodes, QR codes, logos, small text

Squid Ink offers large character, high-resolution, thermal inkjet, small character (CIJ) inkjet printers and laser coders, so you can choose exactly the level of detail your application requires—without sacrificing readability or durability.

- DOD Large Character Printers –DOD Large Character Printers – Squid Ink

- High-Resolution Printers – Hi-Resolution Printers – Squid Ink

- Thermal Inkjet Printers – Thermal Inkjet Printers – Squid Ink

- CIJ Small Character Coders – CIJ Small Character Coders – Squid Ink

- Laser Coding – Laser coder Hi-Resolution products- Squid Ink

3. Production Volume: Planning for Today and Tomorrow

Production volume determines how often your system runs, how much ink it consumes, and how much maintenance it requires.

Consider:

- Daily, weekly, and annual output

- Number of SKUs and changeovers

- Downtime tolerance during peak production

Squid Ink printers are built for continuous operation with minimal maintenance, helping reduce downtime and total cost of ownership—especially important for multi-shift or high-mix environments.

4. Matching Capability to Growth

One of the most common mistakes is buying a system that only fits today’s needs. The right printer should:

- Scale with increased throughput

- Support new substrates and codes

- Integrate easily into existing lines

Squid Ink’s modular designs and broad ink portfolio allow manufacturers to adapt as requirements evolve—without replacing entire systems.

5. The Bottom Line: Balance Is Everything

The “best” industrial printer isn’t the fastest or the highest resolution—it’s the one that delivers:

- The right speed to keep up with your production

- The right quality to meet your compliance and branding needs

- The right capacity to support your growth without excess cost

By balancing speed, resolution, and volume, manufacturers can maximize ROI while maintaining consistent, professional marking across their packaging lines.

Looking to dial in the right configuration for your application?

Squid Ink helps manufacturers assess their production requirements and select marking and coding solutions that fit today—and grow with tomorrow.