Protecting Products and Building Trust: Traceability and Anti-Counterfeiting in the Coding and Marking Industry

In today’s global marketplace, protecting your brand goes beyond high-quality production. With longer supply chains, heightened regulatory scrutiny, and the rise of counterfeit goods, manufacturers face growing pressure to ensure product integrity from production to the point of sale. Traceability and anti-counterfeiting solutions in coding and marking are central to meeting these challenges, helping businesses protect their brand, comply with regulations, and build consumer trust.

Why Traceability Matters More Than Ever

Traceability is the ability to track every product at each stage of its lifecycle — from raw materials to finished goods and beyond. In industries such as food and beverage, pharmaceuticals, and consumer electronics, this capability is critical for several reasons:

- Regulatory compliance: Many industries have strict requirements for tracking products. Food and beverage producers, for instance, must adhere to FDA regulations for lot coding and expiration dates. Pharmaceutical manufacturers face serialization mandates that require unique identification on every package.

- Quality control and recalls: Traceable products enable quick identification of affected batches in the event of defects, contamination, or safety issues. This reduces risk, limits financial loss, and helps maintain customer trust.

- Supply chain transparency: Traceability provides a clear record of where products have been, ensuring authenticity and reducing the risk of diversion or fraud.

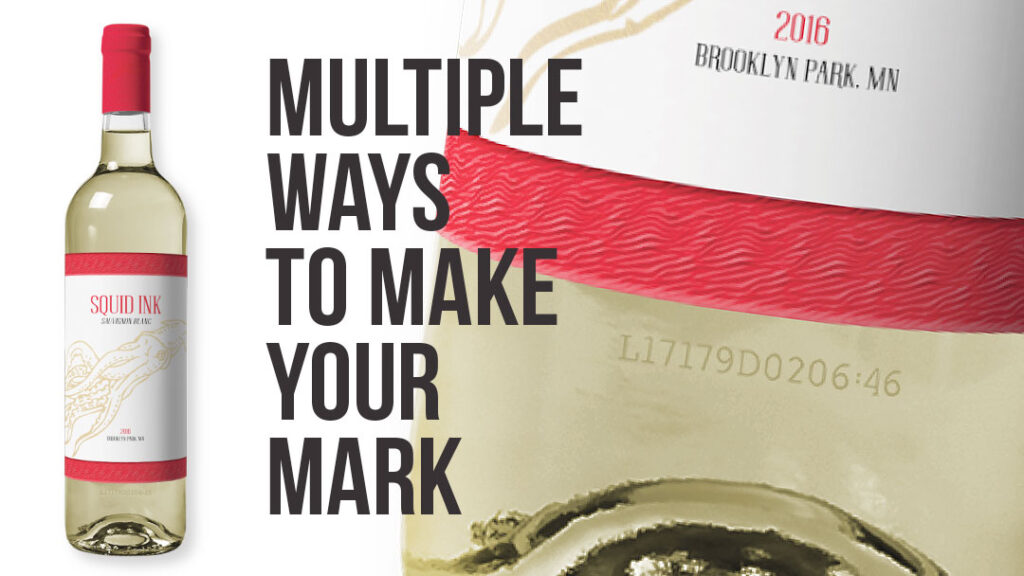

Squid Ink’s advanced coding systems — including hi-resolution inkjet printers, laser coders, and specialty inks — make this possible. By printing clear, accurate, and durable codes directly onto packaging or products, manufacturers gain the visibility they need to track every item throughout the supply chain.

Fighting Counterfeiting: More Than Just a Code

Counterfeiting is a major threat to global business. According to recent studies, counterfeit goods account for hundreds of billions of dollars in lost revenue each year and can seriously damage brand reputation. In some industries, such as pharmaceuticals and personal care, counterfeits can even endanger consumer safety.

To combat this, manufacturers are turning to smarter coding and marking strategies:

- Unique serialization: By assigning a unique identifier to each product, manufacturers can ensure authenticity. These codes can be scanned at multiple points along the supply chain, verifying legitimacy in real time.

- Tamper-evident marking: Squid Ink’s specialty inks and high-resolution printing systems allow for permanent, tamper-resistant codes that are impossible to replicate.

- Complex coding patterns: Incorporating variable data, barcodes, QR codes, and invisible inks adds layers of security, making counterfeiting more challenging.

By combining traceability with anti-counterfeiting technologies, manufacturers not only protect their revenue but also reinforce consumer confidence in their brand.

Leveraging Technology for End-to-End Supply Chain Visibility

Modern manufacturing relies on more than just durable printing — it demands data-driven solutions. Integrating coding and marking technologies with supply chain management systems allows for:

- Real-time monitoring: Track every product as it moves through production, packaging, and distribution.

- Efficient recalls: Quickly isolate affected batches, minimizing the scope and cost of recalls.

- Data analytics: Gain insights into production efficiency, quality trends, and distribution patterns.

Squid Ink’s solutions are designed to integrate seamlessly with these systems, providing reliable, flexible printing processes. From GS1 barcodes to QR codes and custom alphanumeric sequences, our printers handle the most demanding traceability programs with precision and speed.

Real-World Impact: Protecting Brands and Consumers

Traceability and anti-counterfeiting solutions are about more than compliance — they are about trust. Consumers today expect that the products they buy are genuine, safe, and produced with care. Businesses that implement robust coding and marking strategies send a clear message: your safety and satisfaction are our top priorities.

With Squid Ink’s reliable printing systems, manufacturers can:

- Reduce counterfeit risk and protect revenue.

- Maintain regulatory compliance with confidence.

- Quickly respond to product issues and recalls.

- Enhance brand reputation through consistent, high-quality markings.

Conclusion

In an era of global commerce and increasingly sophisticated counterfeit operations, product traceability and anti-counterfeiting strategies are no longer optional. They are essential tools for safeguarding brands, protecting consumers, and building long-term trust.

Squid Ink is committed to helping manufacturers implement these solutions with advanced inkjet and laser coding technologies that deliver precision, durability, and reliability — even in the most demanding production environments.

Protect your products and your brand. Explore Squid Ink’s full range of coding and marking solutions today at squidink.com.