Coding and Marking in the Spirits Industry

Coding and marking play an essential role in the spirits and alcohol industry, particularly in ensuring product authenticity, regulatory compliance, traceability, and branding. These technologies are vital throughout the supply chain, from production to packaging, distribution, and retail. In this blog, we will explore the different technologies and how they are used in the spirits industry.

Types of Coding and Marking

We are going to discuss two main types of coding and marking equipment in the spirits industry: continuous inkjet printing (CIJ) and laser coding.

Continuous Inkjet (CIJ) is the preferred technology for high-speed printing of small characters due to its capability to print at long distances, high speeds, and instant ink drying. An example of a CIJ printing system is Squid Ink’s Jetstream® Sonic, which is commonly used for printing small characters on primary packaged products.

Laser coders use a focused beam of energy to mark a surface through ablation, engraving, or chemical modification (color change). Because they can create high-quality, permanent, discrete marks, laser codes are ideal for applications where presentation and permanency are important.

Laser coders use a focused beam of energy to mark a surface through ablation, engraving, or chemical modification (color change). Because they can create high-quality, permanent, discrete marks, laser codes are ideal for applications where presentation and permanency are important.

Importance of Coding and Marking in the Spirits Industry

Now that we’ve covered the commonly used technologies, let’s discuss their importance in the spirits industry.

Branding: High-quality logos, designs, and texts can be engraved directly onto bottles with laser marking systems, enhancing brand visibility and aesthetics. Limited editions or personalized messages for special occasions can be added, boosting customer engagement.

Permanent Markings: Lasers can create permanent marks that resist wear, moisture, and chemicals, ensuring long-term readability. This is especially important for barcodes, QR codes, and other tracking information that can be laser-etched onto packaging materials, aiding in inventory management and anti-counterfeiting efforts.

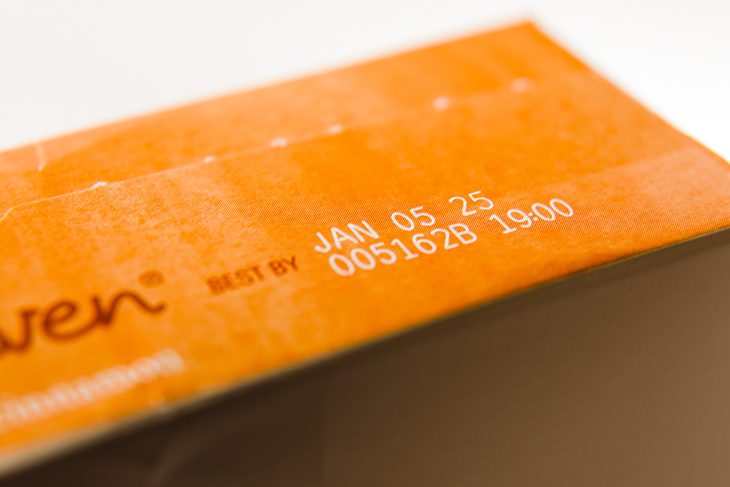

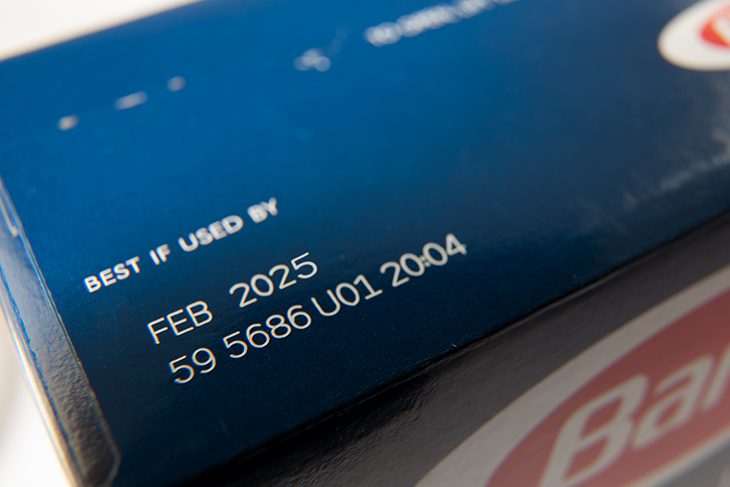

Coding: CIJ printers can print information such as batch numbers, production dates, and serial numbers that can be marked on each bottle or can, facilitating traceability and quality control. This is especially important in the craft brewing industry.

Considerations for Choosing a Marking Solution

Material Compatibility: Different coding and marking technologies are suited to different surfaces (glass, plastic, metal, paper, etc.).

Durability of Marking: Spirits often have a long shelf life, so markings must withstand environmental conditions like moisture, light, and temperature changes.

Cost-Efficiency: Some methods, such as inkjet printing, may have lower upfront costs but require regular maintenance and consumables like ink, while laser marking may have higher initial costs but lower long-term maintenance.

Both laser systems and CIJ printers are great options for the spirits industry. As you have read, it is important to choose the right system for your line, so it is key to consult with a team to figure out what’s best.

To learn more about the coding and marking technologies that Squid Ink offers and how they benefit your operation, visit our product pages and view our full selection of equipment to help you find the right solution for your printing needs!