Squid Ink vs TIJ – The Bakery Edition

We are all familiar with the plastic closures on bread and bagel bags that are used to clip, close, and secure the bag throughout the life of the product. These closures often have printing on them that indicate product pricing, sell by and production dates. For bakeries that produce bread, bagels, and muffins, there are several printing technologies that can be used to print on the closures. Two of the most common technologies are thermal ink jet (TIJ) and hi-resolution UV cure printing from Squid Ink. In this blog, we discuss the advantages of using Squid Ink’s UV cure printing over TIJ printing.

Ink costs add up. When it comes to printing bag closures, a typical bakery will average over 1.5 million prints per cartridge with Squid Ink, or less than 20 cents per thousand. This is 3.5 times less expensive than a typical TIJ printer, and it doesn’t include TIJ cartridges that are discarded due to ink dryout. In this blog, we will talk about the advantages of adding an inkjet printer versus a TIJ printer to your bakery line.

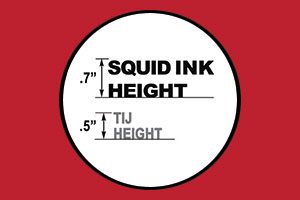

30% Larger Print – Don’t limit your message height: Squid Ink’s CoPilot UV system will print up to .7” vs. .5” max height with TIJ. This allows larger characters and more information on the closure and is ideal for larger bag closures.

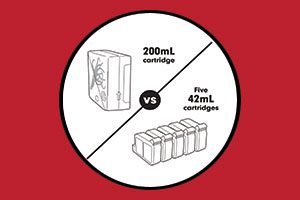

Larger Ink Volume – Squid Ink’s printing system runs 200ml ink cartridges, which are nearly FIVE times the amount of ink compared to the 42ml ink cartridge in a TIJ system. That means five times fewer ink changeovers, less operator involvement, and less chance of running out of ink. Every time you swap out a TIJ cartridge, your printer is down, increasing the chance of missed prints and rework in your operation.

Always Be Printing – Experience maximum uptime with Squid Ink’s 200ml ink cartridge. With a built-in ink reservoir, replacing Squid Ink cartridges is a snap and allows users to continue to run without stopping the production line. Every time you swap out a TIJ cartridge, your printer is down, increasing the chance of missed prints and rework in your operation.

Never Throw Away Unused Ink – Solvent-based TIJ ink cartridges often dry out when not in use, causing users to throw out entire cartridges of ink, whether they are full or empty. Squid Ink’s UV ink only cures when in contact with UV light, so it won’t dry out on the printhead face. This eliminates missing jets, poor print quality, and, best of all, ink you pay for but never get to use!

Increased Throw Distance – Squid Ink printing systems utilize industrial Xaar® print engines, which offer increased printhead to closure throw distance of up to 7mm. TIJ printers recommend that users “kiss” the substrate. Squid Ink’s increased throw distance enables a higher quality mark, ensuring clean, crisp images, razor-sharp text, and scannable bar codes.

Come Over to the Dark Side – Customers shouldn’t have to search for your print. Squid Ink users can expect 30% larger and darker print than TIJ due to larger drop sizes and more ink laydown. The increased height and darkness make Squid Ink the right choice for printing product pricing, sell-by dates, lot numbers, and scannable bar codes that need to be noticed.

Minimize Your Downtime – Squid Ink’s UV ink cures by LED light only and won’t dry out on the printer faceplate. Squid Ink’s UV ink only cures when it comes in contact with the UV lamp. This means minimal maintenance and downtime for your operators and allows them to focus their efforts on other areas of the production line.

Forever is a Very Long Time – Squid Ink’s UV cure system is immediate, and the mark is permanent. There is no warmup time for curing as the system is instant on/instant off. Once cured, the mark is permanent and impervious to sunlight, water, moisture, and contact.

You have the reasons. Now experience the results

For these reasons and more, it is easy to see why Squid Ink’s CoPilot printing system paired with Squid UV Curing is the most cost-effective and lowest maintenance option for bag closure printing applications in the bakery industry. It is easy to see why thousands of these printers have been installed effectively as a proven system in the bakery industry.

But don’t just take our word for it. If you want more information on how this system can benefit your operation, contact Gary Larsen at 1-800-877-5658, or glarsen@squidink.com today!