CoPilot Gemini Hi-Resolution Printer

Water-Cooled UV Curing

CoPilot Gemini

Large Format Printing Versatility

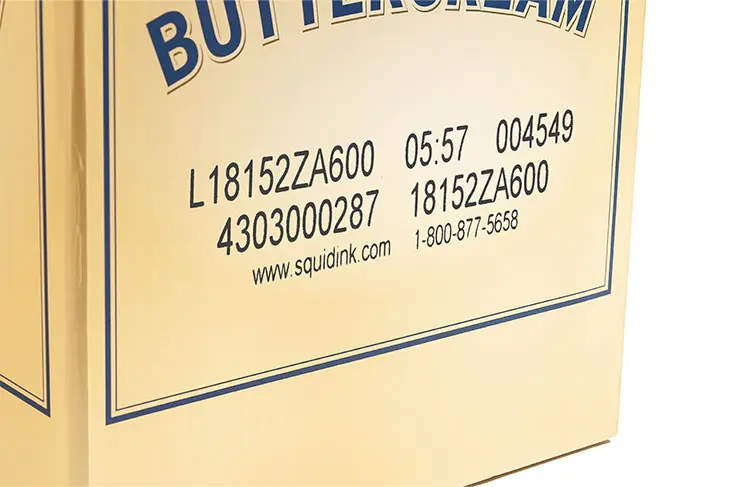

Squid Ink’s CoPilot® GeminiTM printing system is designed to print superior quality hi-resolution characters on porous or non-porous surfaces. For applications that require immediate dry times on non- porous surfaces, the CoPilot Gemini also has the capability to run UV LED curable inks. With a massive 5.6” of print height and print speeds up to 220 ft/ min, the CoPilot Gemini provides a cost effective solution for making your mark on a wide variety of products and substrates.

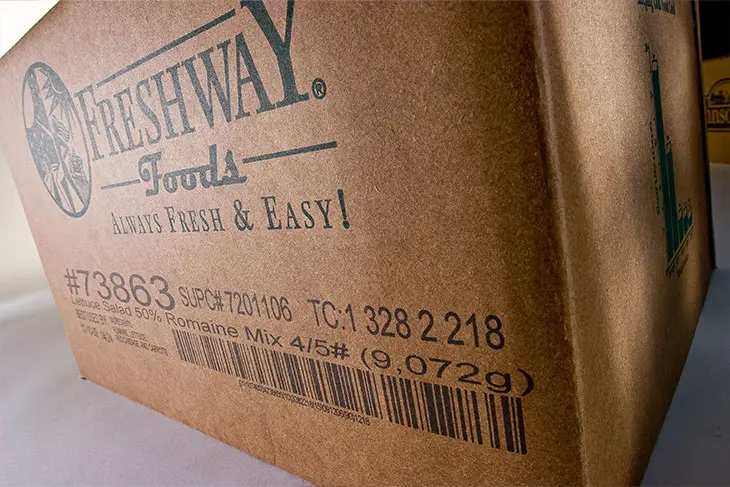

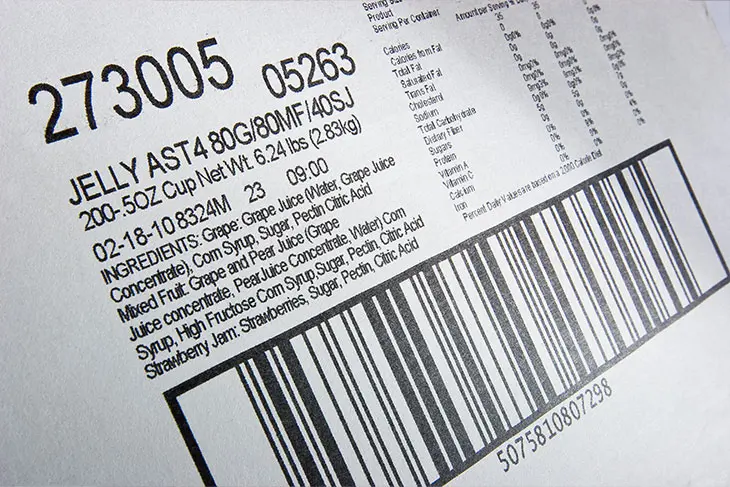

Budget Friendly Label Replacement

The CoPilot Gemini is designed for label replacement. Featuring Squid Ink’s largest printhead with up to 5.6” of print height, the CoPilot Gemini prints high quality 360 dpi GS1 barcodes with ease. And don’t forget that ink jet consumable costs are typically 1/10 of the cost of thermal transfer labels and eliminate preprinted cartons and SKUs of label and ribbon inventory. Get rid of the label and print directly on cartons and cases! Any way you look at it, Squid Ink’s Gemini provides users with an affordable solution to meet their ink jet coding needs.

Production Floor Functionality

Designed with the operator in mind, the CoPilot Gemini features a 4.3” full color touchscreen that allows users to access to the system’s internal messages and print functions. Messages are created and edited on Squid Ink’s easy-to- use OrionTM PC Software and transferred via USB, Ethernet, wireless, or optional Windows® tablet. The large screen 10.1” tablet is ideal for users who want message creation and editing functionality on the production floor. For larger applications, an unlimited number of CoPilot Gemini printing systems can be connected via Ethernet or wireless network and controlled through one central Orion PC.

Designed For Your Application

CoPilot Gemini utilizes the same active ink system found in Squid Ink’s CoPilot Max printing system. The revolutionary design allows users the ability to tilt or rotate the printhead in any direction without making height adjustments to the ink supply. The system prints hi- resolution characters, razor- sharp text, scannable bar codes and great looking logos at industry leading 360 DPI vertical resolution at speeds

up to 220 ft/minute. The CoPilot Gemini also features a large 500ml snap-in cartridge, allowing users the ability to swap ink cartridges in a matter of seconds. The generous ink volume, quick-change ink cartridge, and user-friendly touchscreen design allows users to keep their line running, reducing downtime and maximizing ROI.

CoPilot Gemini’s revolutionary active ink system allows conversion to downshooter mode in seconds.

Squid Ink’s proven inks and fluids are available in large 500ml no-mess cartridges.

The CoPilot Gemini utilizes oil-based, solvent-based, or UV curable inks for printing on a wide range of porous or non-porous substrates.

A 4.3” full color touchscreen provides access to the system’s internal messages and print functions.

BENEFITS OF THE COPILOT GEMINI

- Print Technology – Piezo impulse printhead technology

- Maximum Print Height – 5.6” (14.2 cm)

- Vertical Print Resolution – 360 dpi capable of printing razor-sharp graphics, small character text, and scannable bar codes

- Horizontal Print Resolution – 150 or 300 dpi

- Print Speed – Up to 220 ft/min at 150 dpi; up to 110 ft/min at 300 dpi

- Time & Date – Internal real time clock with battery back-up

- Product Sensor – External photocell or optional encoder

- Communication Interface – One USB host and one Ethernet input

- Touchscreen – 4.3” (10.9 cm) full color touchscreen display

- Ink Cartridge Volume – 500ml cartridge

- Low Ink Indicator – Status alert on touchscreen, light beacon optional

- Substrate Capabilities – Porous or non-porous surfaces

- Electrical Requirements – 100 – 240 VAC, 50/60 Hz, 65W max

- Operating Environment – 34–104°F (1–40°C)

- Agency Certifications – CE

SYSTEM SPECIFICATIONS

- Encoder – For operation with variable speed conveyors

- Bar Code Laser Scanner – Allows scan and print message retrieval

- External Light Beacon – Indicates low ink levels

- Wireless USB Device and Router – For wireless connectivity

- Windows Tablet – Pre-loaded with OrionTM software; includes mounting bracket with swivel arm, USB to ethernet cable and stylus

- Conveyor Mounting Bracket – Provides stable mount to conveyor or other material handling equipment

- Floorstand – Includes mounting brackets and legs with leveling feet; 59” (1.5m) total height

- Spring Loaded Printhead Bracket – Provides consistent throw distance with inconsistent boxes or products

- Starter Kit – Includes ink, cleaner and flush solution, printhead wipes, hand cleaner and latex gloves

SOFTWARE SPECIFICATIONS

- Time & Date – Full time and date functionality including expiration date and Julian Dates.

- Item Numbering – Sixteen counters, one of which can be a daily counter and production counter

- Shift Codes – Four programmable shift codes with automatic rollover

- Bar Codes – All standard bar codes including 2D

- Fonts – Arial, Arial Bold, Arial International, Arial Monospaced, Courier, Tahoma Bold and Lucida resident fonts for use in variable data elements. Static elements in any Windows® font

- Logos – Most image files supported with Orion software

- Printing Features – Reverse, invert, rotate, repeat; print on/off button

- Message Length – Up to 120” (3.05 m)

- Number of Messages – 1GB storage space will store approximately 1000+ messages

- Ink Usage – Shown in Orion software

- User Data Prompts – Prompts for user input at start of print job by manual input on touchscreen

- Wireless Connectivity – For wireless connection between PC or tablet and printer controller

- Database Capability – Ethernet communication protocol for external communication

- Languages – English, Spanish, German, Chinese, Japanese, Korean, Russian, Polish

Videos

Samples

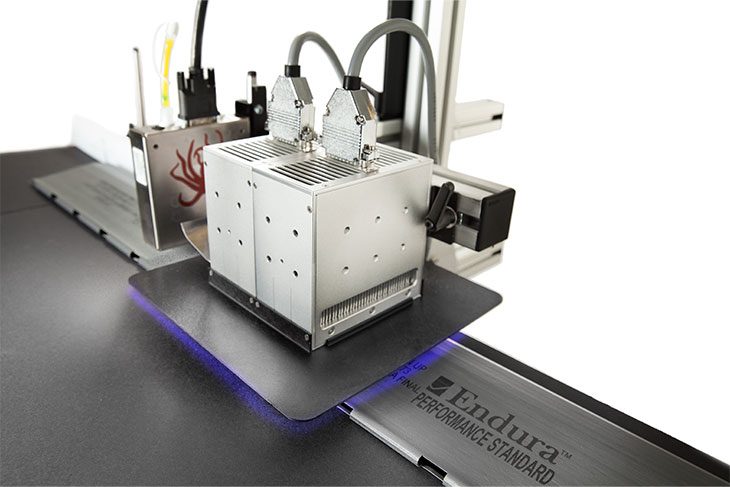

UV Curing System

The Squid UV LED Curing System from Squid Ink offers accurate and consistent UV curing across a variety of commercial and industrial applications. Whether you need to cure ink on metal, glass, automotive products, plastics, electronics and more, you’re sure to find the right solution with Squid Ink’s new UV Curing System.

High Curing Quality

Squid UV is capable of curing inks in a 20mm x 80mm area from a single illumination module that can be doubled to cure an area of 40mm x 80mm or 20mm x 160mm with the addition of a second system. The system features an advanced LED module to provide consistent luminance, resulting in a reliably cured product, every time. The stability of UV LED technology makes the output of electricity predictable and stable, avoiding problems associated with conventional halogen heat lamp drying.

Low Running Cost

UV LED technology provides a stable and efficient way of curing CIJ, Piezo, and Thermal inkjet inks. The integrated super cooling system considerably lowers the unit’s operating temperature to extend the life of the machinery while reducing maintenance costs. The use of UV LED curing results in a significant savings in power reduction, and time and money spent replacing lamps becomes obsolete due to the 20,000+ hour illumination runtime. For comparison, Squid UV curing systems use about 75% less energy than typical UV arc lamp curing

Squid UV LED offers instant on / instant off curing.

Standard bracketry allows Squid UV LED to mount directly to your existing manufacturing line.

Adjustments are easily made with the simple-to-use touchscreen interface.

Squid UV LED provides reliable curing on coated cartons, plastics, metals, foils, film, rubber, and more.

BENEFITS OF THE UV LED CURING SYSTEM

- Single head curing area of 20mm x 80mm

- *Dual head curing area of 40mm x 80mm or 20mm x 160mm

- Stable and efficient way to cure ink

- 20,000+ hour illumination run time reduces cost associated with lamp replacement

- Small footprint allows for ease of integration on existing conveyor lines

- Increase production rates while eliminating lengthy dry times

SYSTEM SPECIFICATIONS

- Wave Length – 395 ± 5nm

- Irradiancy – 12W / cm ²

- Effective Illumination Area (Single Head) – 20mm x 80mm

- Effective Illumination Area (*Dual Head) – 40mm x 80mm or 20mm x 160mm

- Recommended Illumination Height – 1.5 – 10mm from substrate

- Production Line Dry Time – Up to 35m/min depending on substrate

- Control Modes – Manual or Automatic

- Controller Dimensions – 13” x 9” x 5.2” (33cm x 23cm x 13cm)

- Illuminating Head Dimensions – 4.7” x 2.6” x 4.7” (12cm x 7cm x 12cm)

- Lamp Shield Dimensions (Single Head) – 9” x 6.7” (23cm x 17cm)

- Lamp Shield Dimensions (*Dual Head) – 9” x 9.3” (23cm x 24cm)

- Illuminant Output Control – 10% – 100%

- Power Supply – 90 – 220V AC 50/60Hz 500W (single head) 1000W (dual head)

- LED Lifetime – 20,000 hours or more

- Working Environment– 32°F (0°C) – 95°F (35°C)

- Storage Environment – 14°F (-10°C) – 140°F (60°C)