Water-Cooled UV vs Air-Cooled UV

First off – what is UV LED Curing?

UV LED technology provides stable and efficient curing of CIJ, Piezo, and Thermal UV-curable inkjet inks. UV LED curing, which stands for ultraviolet light-emitting diode, is the process of hardening liquid ink, adhesive, or coating from exposure to ultraviolet light. Photo-initiators in UV-curable ink react and cross-link or polymerize, forming a hardened, dry film.

UV LED curing technology can be used for visible lighting, water purification, nail curing, and many other applications. It can also be used in industrial applications with products like Squid Ink’s UV LED curing system. Squid Ink’s system uses UV LED technology to cure ink on metal, glass, automotive products, plastics, electronics, and more.

What is water-cooled UV curing?

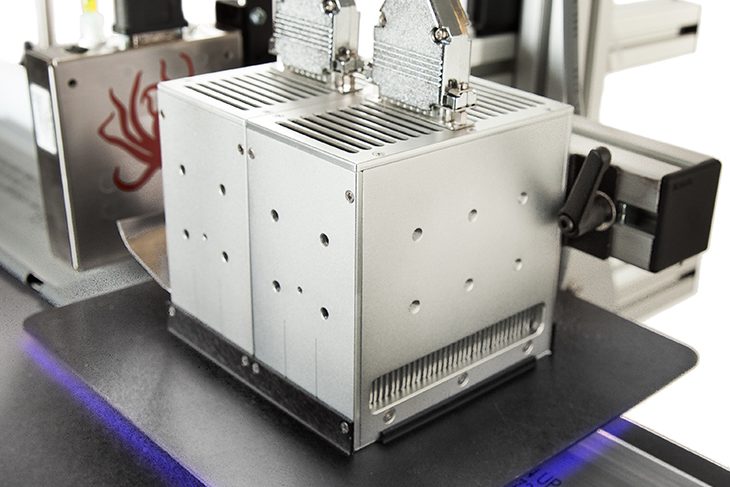

Water cooling systems utilize an independent water cooler to circulate water and maintain precise temperature control. Squid Ink’s water-cooled system consists of a chiller, a water-cooled lamp module, and a controller. The chiller continuously circulates 6 liters of cool water through the UV lamp. Cold water flows in, heated water flows out and then returns to the chiller to be cooled. Water-cooled systems are ideal for demanding production environments where consistent performance under high workloads is crucial, and where it’s important not to impact the local environmental conditions.

Let’s Compare: Water Cooled and Air Cooled

Water-cooled and air-cooled UV systems are great for packaging lines, but there are differences. In comparison to an air-cooled system, the water-cooled system runs cleaner with no airflow or air movement to blow dust and debris on the product. Water-cooled systems also run much quieter, as noisy air fans are not running to keep the lamp module cool.

The integrated chiller and water-cooled system significantly lower the unit’s operating temperature, extending the life of the machinery and reducing maintenance costs. UV LED curing results in substantial power savings, and the time and money spent replacing lamps becomes unnecessary.

An air-cooled system is a great choice for environments seeking a simple, easy-to-integrate system. A straightforward system like an air-cooled machine allows easy maintenance and lower costs.

In any case, both Squid Ink UV LED curing systems are an ideal alternative to mercury arc lamps. Squid Ink’s UV LED curing system has a lifespan of around 20,000+ hours, significantly higher than a mercury arc lamp’s 500 to 2,000-hour life. Additionally, Squid UV curing systems use about 75% less energy than typical mercury arc curing lamps. Reduced power consumption helps extend the lifespan of the system.

Although mercury arc lamps are still in use, UV LED curing is gradually becoming more popular because it is more environmentally friendly, longer lasting, and less costly. Also, the need for exhaust systems to prevent contaminated air when using mercury vapor systems is causing many manufacturers to switch to newer UV LED curing technology.

Want to learn more about Squid Ink’s Squid UV LED Curing Systems? Visit the UV LED Curing section of our website for more information, send us an email, or give us a call at 1-800-877-5658.