TIJ vs. CIJ

Thermal inkjet printers and continuous inkjet printers have gained popularity over the years, but which printer is the best fit for your packaging line? We discuss the differences between these printers and their advantages in the article below.

What is Continuous Inkjet Printing (CIJ)?

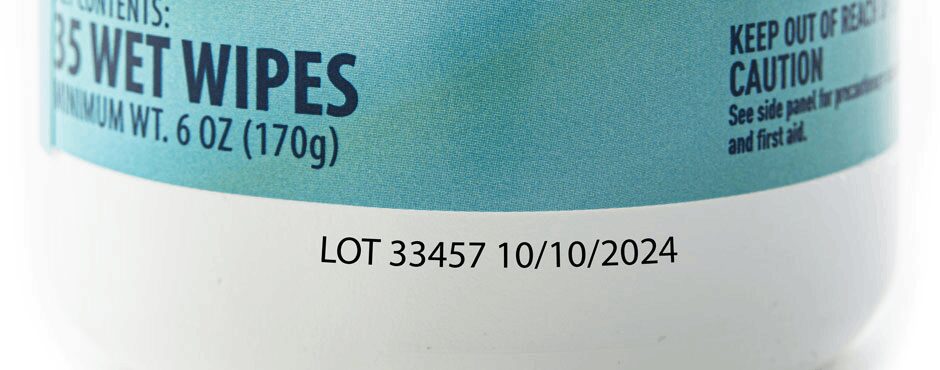

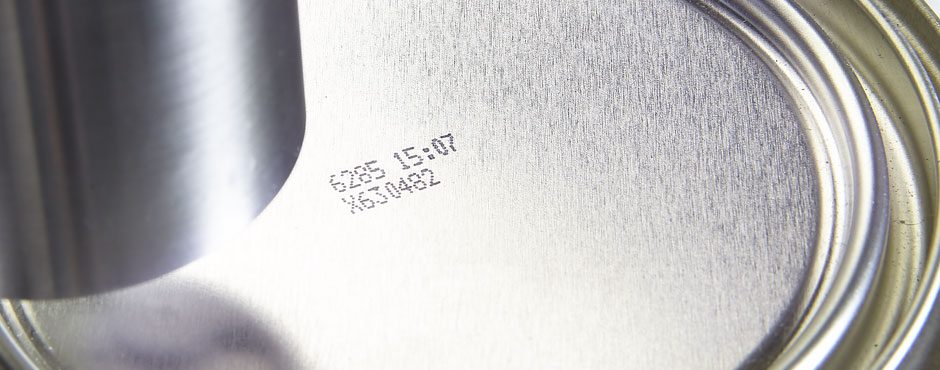

CIJ is the technology of choice for small character high-speed printing. Like Squid Ink’s JetStream Sonic, CIJ printing systems are used for small character printing and are typically used in primary package and high-speed product marking applications. The JetStream Sonic can print up to five lines of text up to 1,200 feet per minute. Two other reasons that CIJ is a preferred method over others are its long throw distance and ability to use MEK-based inks that allow for immediate drying. Next time you are in a grocery store, take a closer look at the products on the shelves. Many of these small character codes are on items you would see daily, such as date codes printed on the bottom of cans, expiration dates on a milk jug, and many other products.

What is Thermal Inkjet Printing (TIJ)?

Thermal inkjet printers utilize replaceable cartridge printheads to print codes on both porous and non-porous substrates. The cartridge contains multiple ink nozzles, with each containing a heating element. The coil heating element is charged with a current in the ink chamber above the nozzle, and when a current of heat is passed through the ink chamber, an ink droplet is ejected. This increase in pressure allows for an ink droplet to go through the nozzle and onto the substrate. TIJ nozzles are microscopic, and resolutions up to 600 dpi are standard.

Print Speeds

Thermal inkjet printers and continuous inkjet printers are great for coding and marking, but they have several differences. For example, while a TIJ printer can print at fast speeds (Squid Ink’s standard Viper TIJ printer runs up to 197 fpm, with optional speeds up to 787 fpm), Squid Ink’s JetStream Sonic has a print speed of up to 1,200 fpm, making it the faster option.

Throw Distance

TIJ printers have a small throw distance, the ideal distance being about 1/8’’ from the substrate. The reason for the smaller throw distance is to ensure the printer produces a legible print. On the other hand, a CIJ printer has a throw distance up to an inch, allowing for a wider range of possible printing applications and product shapes.

Substrates

Both printers are great for printing onto porous and non-porous surfaces. With their quick-dry ink, TIJ printers are great for printing on non-porous surfaces. CIJ printers also use ink that readily adheres to non-porous surfaces. When it comes to substrate flexibility, both TIJ and CIJ printing systems are a good option.

Ease of Integration

Thermal inkjet printers can be easily integrated into most packaging lines due to their small footprint. In addition, TIJ systems come with a quick system setup and print cartridge change-over, resulting in reduced downtime due to system downtime. Overall, TIJ systems have little to no maintenance costs when compared to CIJ systems.

CIJ printing systems can be easily added to an existing production line; however, space needs to be considered when adding a CIJ system due to their larger cabinet and print head size. Additionally, CIJ printers typically require more maintenance than TIJ printing systems. Therefore, it is important to have trained users on hand if the system requires maintenance.

In the end, both systems are great for primary coding and marking applications and would be great additions to your packaging line.

To learn more about the marking and coding solutions that Squid Ink offers, visit our product pages, or give us a call and learn more about how we can help you code the products you deliver to the world.